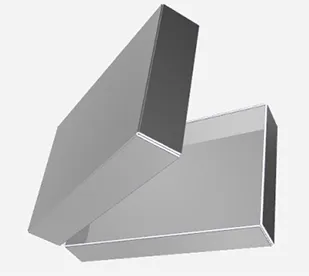

The Automatic Rigid Box Wrapping Machine automates wrapping, ensuring smooth, even coverage with minimal wrinkles. Specialized machines in rigid box manufacturing ensure precision and efficiency. This rigid box wrapping machine sets itself apart from traditional ones by eliminating the need to change the pressure plate or blade during operation. Instead, the operator simply inputs the desired product size, and this paper box forming machine automatically adjusts the mold with precision and accuracy. This saves time and minimizes errors, resulting in a lower failure rate.