The equipment uses servo motors to provide power and achieves precise control of various actions through pneumatic technology. Servo motors have the characteristics of high precision, high stability, and high response speed, ensuring the stable operation and precise control of the equipment.

Servo motor: XINJE (China)

Motion Control PLC: XINJE (China)

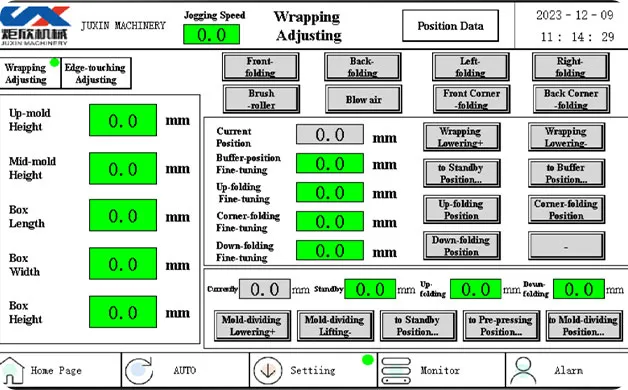

7-inch touch screen: WEINVIEW (Taiwan)

Cylinder components: Air TAC (Taiwan)

Guide rail: Air TAC (Taiwan)

Screw rod: Egus (Germany)

Travel limit switch: Schneider (France)

Button switch: Schneider (France)

Plastic bearings:Egus (Germany)

Bearing: Harbin (China)

Safety Light Curtain: Panasonic (Japan)

Precision Pressure Regulating Valve: SMC(Japan)

Digital pressure gauge: SMC(Japan)

Download

Download