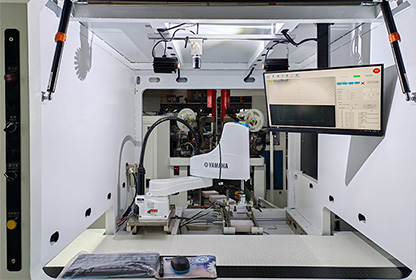

Feida automatic paper feeding and gluing machine is a kind of equipment commonly used in paper production. Its working principle is to feed the pre-cut paper into the equipment through the transmission belt, and then locate it to the appropriate position through the fast and accurate positioning system, and then use the automatic glue spraying system to spray glue, and finally use the transmission belt to send it out.

Download

Download