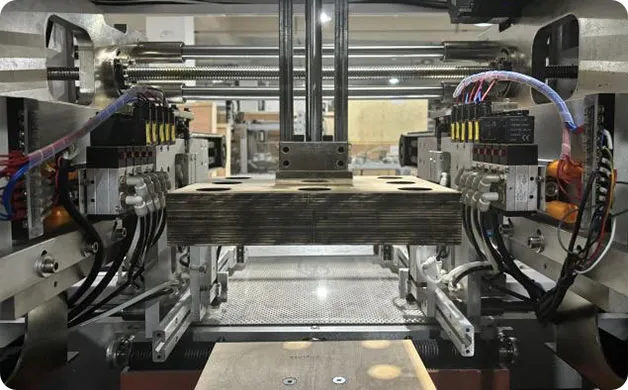

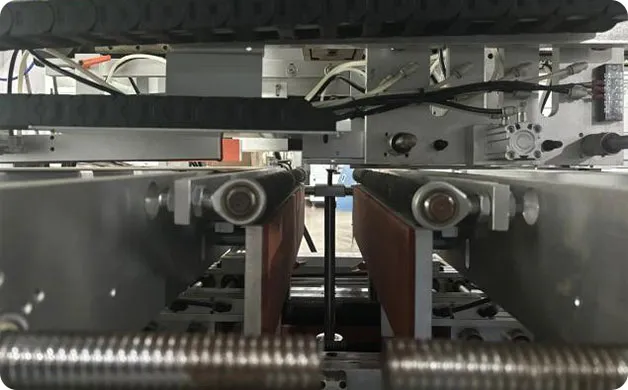

The automatic sensing arm can precisely control the operation process, achieve fast and accurate operation, reduce waiting and idle time in the production process, and significantly improve the production line's capacity. In addition, they can complete a large number of repetitive tasks within a specified time frame

Servo motor: XINJE (China)

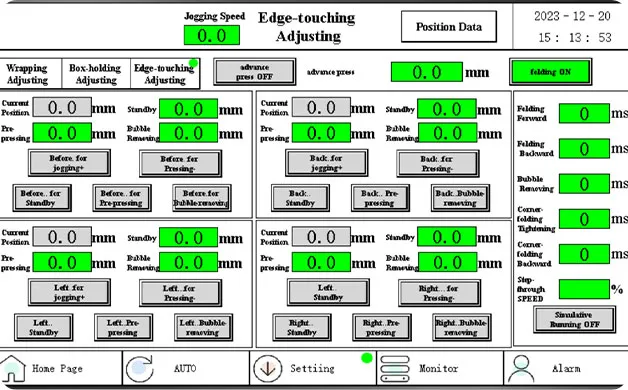

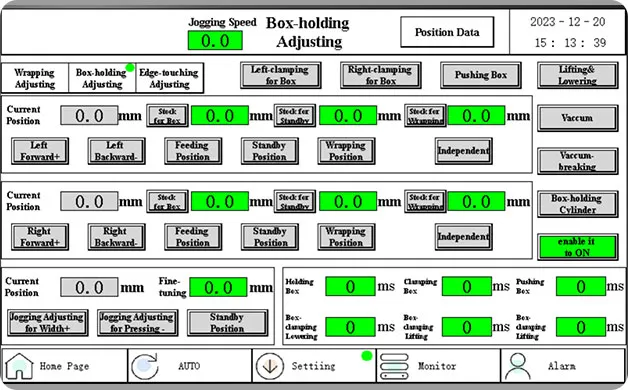

Motion Control PLC: XINJE (China)

7-inch touch screen: XINJE (China)

Cylinder components: Air TAC (Taiwan)

Guide rail: Air TAC (Taiwan)

Screw rod: Egus (Germany)

Travel limit switch: Schneider (France)

Button switch: Schneider (France)

Plastic bearings: Egus (Germany)

Bearing: Harbin (China)

Precision Pressure Regulating Valve: SMC (Japan)

Digital pressure gauge: SMC (Japan)

Download

Download