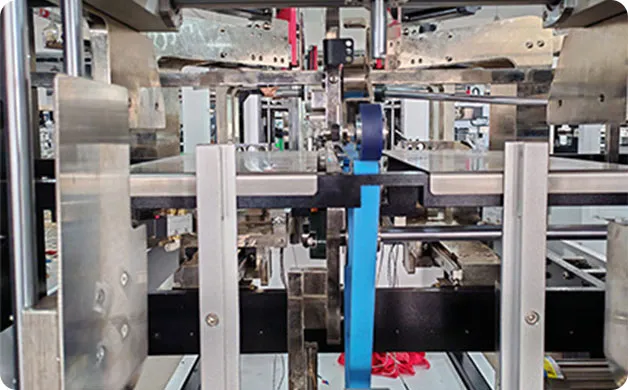

The fully automatic corner sticking machine adopts a PLC servo system and precision photosensitive eye control. The conveyor belt is stable and does not shake, and it can accurately complete the set instructions to achieve the designated position of the corner edge labeling.

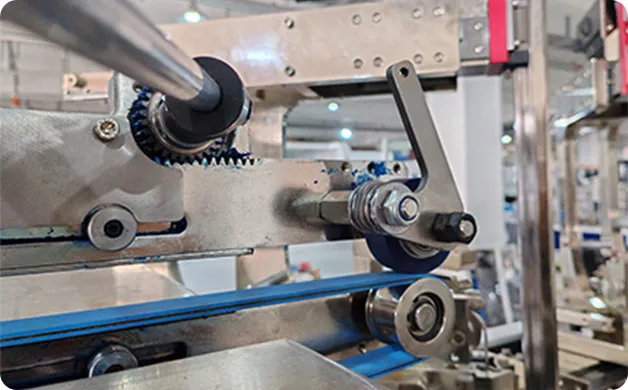

Servo motor:XINJE (China)

Motion Control PLC: XINJE (China)

7-inch touch screen: WEINVIEW (Taiwan)

Cylinder components: Air TAC (Taiwan)

Guide rail: Air TAC (Taiwan)

Screw rod: Egus (Germany)

Travel limit switch: Schneider (France)

Button switch: Schneider (France)

Plastic bearings:Egus (Germany)

Bearing: Harbin (China)

Download

Download