A Beginner's Guide to Gift Box Packaging Machinery: Start Your Journey to Exquisite Packaging

Dec 15,2025

Dec 15,2025In today’s thriving gift economy, gift box packaging serves as a key carrier of emotion and value. For newcomers stepping into the world of gift box packaging, understanding the basics of packaging machinery is the first step toward achieving efficiency and beauty in production.

Types of Gift Box Packaging Machinery

Automated Packaging Lines

Large-scale gift box manufacturers often prefer fully automated packaging lines. These integrated systems perform a series of precise operations—from feeding and positioning to folding, gluing, sealing, and labeling—seamlessly and continuously. Utilizing advanced PLC control systems and sensor technology, the production line accurately controls each packaging stage. For example, when producing standard square gift boxes, sensors measure paperboard dimensions precisely, while the PLC guides robotic arms to pick and fold the board, ensuring dimensional accuracy and a neat appearance. Automated lines are also highly flexible, easily adapting to various sizes, from delicate jewelry boxes to larger storage gift boxes.

Semi-Automatic / Manual-Assist Machines

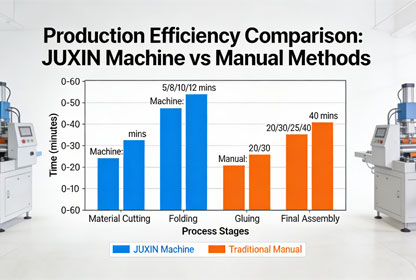

For small-scale production or businesses focused on custom gift boxes, semi-automatic or manual-assist machines are ideal partners. Simple in design and easy to operate, they allow operators to complete part or all of the packaging process with mechanical assistance. A manual folding machine, for instance, can fold gift box paperboard in seconds—a task that might take minutes by hand. Similarly, hot glue guns offer better control over adhesive application compared to manual gluing, resulting in stronger and cleaner edges. While these machines may not match the speed of automated lines, they offer great flexibility for complex designs and personalized orders, such as uniquely shaped boxes for vintage-style packaging.

Custom-Built Packaging Machines

As market demands evolve, custom-built packaging machines have emerged to meet specific functional or technical requirements. These machines are designed and manufactured based on a client’s exact needs. For example, if you package high-end jewelry, you could order a machine with precise positioning and anti-vibration features. Such a machine might include specially designed slots to secure items and integrated cushioning materials like foam or sponge. For eco-friendly gift boxes, you could also develop systems that use biodegradable adhesives, aligning with sustainable packaging trends.

Key Operating Guidelines

Pre-Start Preparation

Before starting any packaging machine, proper preparation is essential. Ensure the equipment is placed in a well-ventilated area with easy access for cleaning and maintenance. Install the air supply correctly and verify that the air pressure meets the machine’s requirements—different models have different specifications. Next, check that the power supply matches the machine’s standards before plugging it in. Thoroughly clean all components to remove dust or debris, which helps maintain hygiene and performance. Finally, secure the safety lock and switch on the power.

Parameter Settings

Take a common 3D transparent film wrapping machine as an example: after turning on the touchscreen, you’ll need to enter parameters such as box length, width, height, and thickness. Accurate input is crucial—incorrect settings may lead to poorly wrapped boxes or uneven surfaces. Always measure the actual box dimensions carefully and enter them precisely into the control system.

Operating Workflow

Once the machine is started and parameters are set, the packaging process begins. For a standard cartoning machine:

•The feeding system smoothly transports products into the loading area.

•The box opening system—often using suction cups—picks and opens each flat box.

•The loading system then places the product into the box accurately via robotic arms or pushers.

•The sealing system follows; for example, hot melt glue may be applied to securely close the lid.

•Finally, the sealed boxes are conveyed out for the next stage of packaging or dispatch.

Maintenance & Care

Daily Cleaning

Routine cleaning is fundamental. After each use, remove any residual glue, paper scraps, or dust from the machine surfaces. Use compressed air to blow away debris from hard-to-reach areas. For instance, clean the nozzle of a hot glue gun promptly to prevent clogging. In automated lines, regularly clean mechanical parts and conveyor belts to ensure smooth operation.

Regular Inspections

Periodically check key components of the machine. Examine transmission parts such as chains and gears for wear or looseness—worn chains can cause unstable operation and affect packaging precision. Inspect heating elements (e.g., in hot melt systems) to ensure even heating performance. Also, review electrical connections for any signs of damage to maintain safety.

Replacing Wear Parts

Some components naturally wear over time and require timely replacement. Cutting blades, for example, may become dull after extensive use, affecting sealing quality. Rubber pads, seals, and gaskets can degrade or deform, reducing machine efficiency. Always use replacement parts that match the original specifications to keep your equipment running reliably.

Start Your Packaging Journey with Confidence

Gift box packaging machinery may seem complex at first, but by learning the different machine types, mastering operational steps, and following consistent maintenance routines, beginners can gradually build expertise. With the right equipment and knowledge, you can create stunning, high-quality gift packaging that stands out in the market.