Complete Guide to Festival Gift Box Production

Aug 19,2025

Aug 19,2025Behind every eye-catching chocolate hamper or intricate mooncake box lies a blend of precision engineering and smart printing. For businesses, this isn’t about packaging; it’s about unlocking revenue during peak seasons while standing out in crowded markets. Here’s how the right technology transforms raw materials into profit-driving festival masterpieces.

1. Precision Cutting: Unlocking Potential in Every Sheet

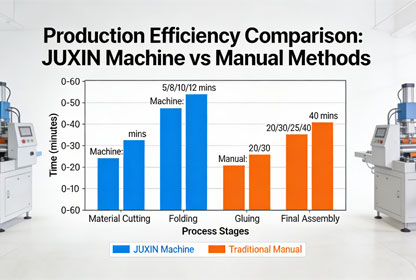

The unsung heroes of gift box production are sheet cutting machines. Forget uneven cuts and manual labor. By handling paper, cardboard, and foils with micron-level precision, automated mold adjustment box-making machines can reduce waste by up to 14%. Speed is a must for seasonal surges (such as Valentine’s Day boxes or mooncakes). Laser-equipped cutters combine design flexibility with merciless efficiency, processing volumes 30% faster than conventional techniques.

Why festivals care about it: Cutting intricate shapes (layered drawers, hearts) requires precision. Production can be halted before printing even starts by a single misaligned sheet.

Astute integration To maximize material layouts and control costs when using textured stocks or specialty foils, pair cutters with automated nesting software.

2. Commercial Printing: A Color Market

Technical and artistic abilities are combined in commercial printing. Unlike desktop printers, industrial inkjet systems can create vibrant, smudge-proof images up to twice as quickly. For seasonal boxes, this suggests the following:

Photo-realistic finishes include metallic reds, gradient golds, and tactile textures (like the “woven silk” effects on high-end mooncake boxes).

Cost control: Compared to consumer equipment, high-capacity ink systems save 60–70% on cost per print when producing thousands of units.

Agility in the short term: Quickly switch to 500 gold designs for supermarkets after printing 50 red boxes for a boutique order.

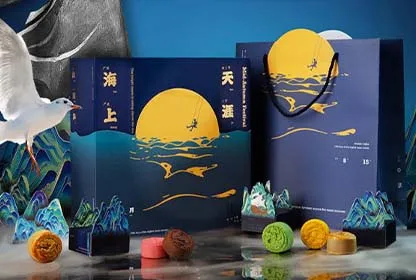

3. Festive Case Study: Magical Mooncake Containers

Consider Mid-Autumn Festival boxes. Combined traditional weaving motifs with modern durability. The tech stack did the following:

Cutting: Lasers were used to carve delicate "bamboo lattice" windows into rigid boards.

Printing: Glistening champagne-gold gradients were applied to matte stock using commercial inkjets.

Assembling: Automatic folders with magnetic closures and interiors lined with silk.

Valentine’s Day chocolate trays, Diwali sweet boxes, and Christmas gourmet sets all use comparable procedures.

4. Your Turn: Resources for the Upcoming Festival Bust

Avoid betting on out-of-date equipment. From high-volume printers to intelligent sheet cutters, today’s integrated solutions convert seasonal fluctuations into steady profit.

Ready to craft unforgettable festival boxes? → GET A QUOTE