Why Lid and Base Boxes Demand Specialized Equipment

May 19,2025

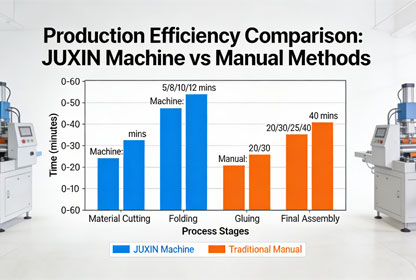

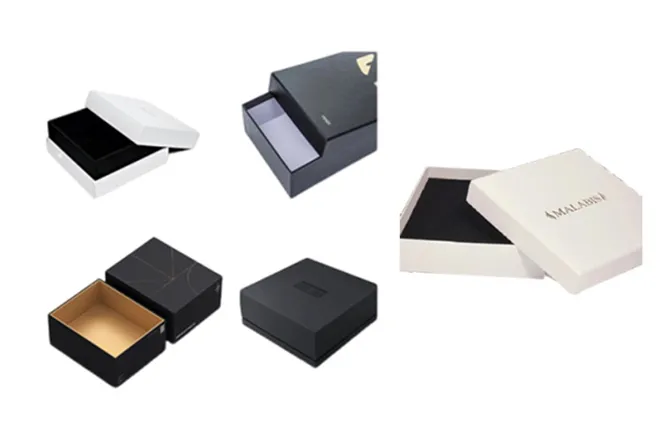

May 19,2025Rigid lid and base boxes are still the best for presenting high-end products. High-value items are protected by their independent top-to-bottom construction with reinforced walls, which also provides an excellent unboxing experience. Bottlenecks are caused by traditional manual production methods, which include cutting boards, laminating materials, and precise wrapping:

Unreliable alignment of corner folding (variance of ±12mm).

Labor costs are 60% higher than with automated lines.

Limited ability to handle spikes in seasonal demand.

These difficulties are resolved by integrated automation in contemporary rigid box making machines and rigid box wrapping machines. Sophisticated systems ensure that every lid and base box meets precise specifications, from small jewelry cases measuring 100x50x12mm to gift collections measuring 600x400x130mm. These systems handle adhesive application, cover material wrapping, and corner folding within ±0.2mm tolerances.

Engineering Breakthroughs in Automation

Today’s automatic rigid box production lines integrate proprietary technologies for unmatched reliability:

Zero-Defect Wrapping: Hydraulic-pneumatic corner folders with independent heating zones prevent material warping for leather, velvet, and metallic finishes

Intelligent Changeovers: PLC systems store 300+ box recipes – switch between lipstick cases and whiskey gift sets in <3 minutes

Resource Optimization: Glue viscosity controls reduce material waste by 28%; servo motors lower energy consumption 22% vs. conventional machines

Self-Monitoring Performance: IoT sensors track paper tension, adhesive temperature, and alignment in real-time

Industry-Specific Applications

Automatic rigid box wrapping equipment delivers ROI where packaging equals brand value:

Jewelry Sector: Produce velvet-lined boxes with magnetic closures (50200 units/hour)

Electronics Manufacturers: Create foam-inserted iPhone/watch cases with scratch-resistant lamination

Premium Beverages: Output foil-stamped whiskey/cognac boxes with embossed logos

Seasonal Goods & Cosmetics: Scale mooncake or perfume box production to 15,000 units/day without quality drop-off. Quick-change tooling handles intricate designs like drawer boxes.

Transform Your Packaging Capabilities

Manual rigid box production costs manufacturers an average of $3.50-$7.00 per unit in labor, waste, and rework. For a mid-sized producer making 200,000 boxes annually, that’s $700,000-$1.4M in avoidable expenses. Stop losing profits to manual inconsistencies.

Get Your Efficiency Upgrade→[Contact us]