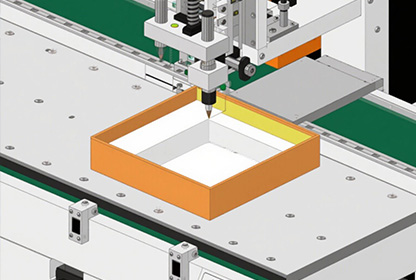

Glue saving and environmental protection: The gluing machine can accurately control the amount of glue used to avoid waste, and use environmentally friendly glue to reduce the impact on the environment.

Anti-rolling device: The gluing machine is equipped with an anti-rolling device to prevent hands and workpieces from being rolled into the glue storage tank and roller to ensure safe operation.

Uniform gluing: The gluing machine can ensure uniform gluing, no glue dripping, no glue leakage, and quick and neat glue cutting to improve product quality.

Automatic control: The built-in time control device can accurately and automatically cut off the glue to improve production efficiency and product quality.

Accurate temperature control: The temperature control of the gluing machine is very accurate, with an error of only 0.5 degrees, which is suitable for gluing and forming of various materials.

Uniform glue coating and adjustable thickness: The gluing machine has uniform glue coating, and the glue coating thickness and speed can be adjusted according to needs to meet different production needs.

Short melting time: The melting time of modern gluing machines is short, only ten minutes, while traditional gluing machines take about 30 minutes. 2. Power saving: Compared with similar offset printing machines on the market, the gluing machine consumes less power when working, saving electricity2.

Safety protection: The gluing machine has triple self-protection functions to ensure the safe operation of the equipment

Download

Download