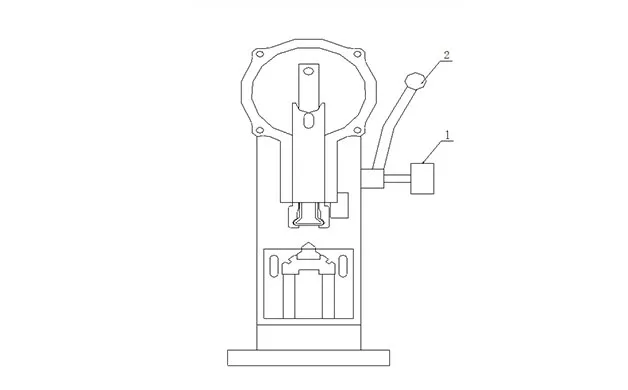

Compared to other types of corner sticking machines, manual corner sticking machines are relatively inexpensive and suitable for use by small and medium-sized enterprises.

The manual corner sticking machine is suitable for various types of boxes and can meet different packaging needs.

Download

Download