Adhering to National Standards, Juxin Machinery Forges Ahead

Nov 20,2025

Nov 20,2025In the booming manufacturing industry, a company’s survival and development depend on upholding quality and standards. Founded in 2011, Wenzhou Juxin Machinery Co., Ltd. has deepened its roots in the field of automated gift box machinery. Strict adherence to national standards runs through every stage of its development, serving as a solid foundation for steady progress.

Upholding Standards Throughout Development

Based in Rui’an, Zhejiang Province, Juxin Machinery targeted the niche market of automated gift box equipment from its inception. While domestic industry standards were gradually established, some enterprises failed to fully implement them. Juxin, however, took national standards as the fundamental principle for production and operation. It organized technicians to study relevant mechanical industry standards, ensuring strict compliance in structural design, part processing precision, and performance testing.

As the company expanded its product line—from initial integrated heaven-and-earth cover equipment to laminating machines, slotting machines, and integrated folder equipment—national standards continued to evolve. In 2017, the Standardization Administration of China launched the development plan for the national standard series General Technical Conditions for Heavy Machinery (16 parts), imposing stricter requirements on design, manufacturing, and inspection. Juxin responded promptly by optimizing production processes: upgrading welding equipment, introducing advanced techniques, and training workers to meet the new standards for weld quality and materials, significantly enhancing product stability.

Product Types Aligned with Standards

Fully Automatic Rigid Box Making Line

Widely used in gift packaging, this equipment adheres to national standards for safety and stability. Its electrical system features multiple leakage and overload protection devices, ensuring operator safety. Key components like transmission systems and molds use high-quality steel meeting mechanical material standards, enabling high-precision production and reliable long-term operation.

Cover Machines

Critical for cover bonding, Juxin’s cover machines meet packaging machinery standards for precision. Equipped with high-precision sensors and control systems, they minimize bonding errors. The equipment uses low-VOC environmentally friendly adhesives and optimizes application systems to reduce waste and emissions, complying with national environmental standards.

Slotting Machines

Used for precise slotting in cardboard, these machines adopt cutting tools that meet national safety and service life standards, preventing safety hazards like blade chipping. Designed with ergonomic principles, the equipment features intuitive control panels to reduce operator fatigue and improve efficiency.

Integrated Folder Equipment

Covering the entire process from sheet processing to folder forming, this equipment uses raw materials from certified suppliers with quality inspection reports. Assembly strictly follows mechanical fitting standards—for example, adjusting transmission chain tension to ensure smooth operation and avoid failures.

Achievements of Standard Compliance

Market Recognition

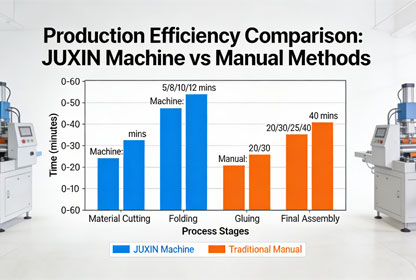

Juxin’s high-quality, stable products are sold in over 30 domestic provinces and exported to multiple overseas countries. A large food enterprise reported a rise in daily gift box output from 5,000 to 8,000, with defect rates dropping from 5% to below 1% after adopting Juxin’s equipment. International certifications, based on strict national standard compliance, have earned the company a strong global reputation.

Technological Innovation

Complying with standards has driven innovation. For example, the 2025-patented "low-noise two-stage cylinder" was developed to meet national industrial noise control standards. By optimizing structural design, it reduces operational noise significantly, enhancing product competitiveness and advancing industry noise control technology.

Significance and Challenges

Significance

•For the company: Standard compliance boosts credibility, expands market share, optimizes processes, and reduces costs (e.g., lower defect rates and environmental governance expenses).

•For the industry: It promotes standardized development, encourages healthy competition, and enhances the sector’s global competitiveness.

•For society: It improves production safety and supports sustainable development through environmental protection.

Challenges

•Continuous updates to national standards require ongoing investment in personnel training and process adjustments.

•Non-compliant low-cost competitors disrupt the market.

•Fluctuations in raw material quality from suppliers may affect product standard compliance.

Future Outlook

JUXIN will continue adhering to national standards amid the deepening of intelligent and green manufacturing. It plans to invest more in R&D, integrating advanced sensors, AI, and control systems to upgrade equipment intelligence, meeting national smart manufacturing standards. In green manufacturing, the company will optimize product design and processes, adopting eco-friendly materials and energy-saving technologies. Additionally, Juxin will participate in national standard formulation and revision, contributing industry experience to drive sector development.