High-End Gift Boxes Returned Due to Color Deviation: How to Address the Pain Points in the Packaging Industry (Part 2)

Oct 15,2025

Oct 15,2025In today’s fiercely competitive business environment, packaging, as the "first impression" of a product, is of undeniable importance. For high-end gift boxes, they further bear the crucial responsibility of embodying brand image and conveying emotions—every detail can determine success or failure. However, the phenomenon of high-end gift boxes being returned due to color deviation occurs from time to time. This not only causes economic losses to manufacturers but also damages brand reputation, while also exposing the deep-seated pain points in color management within the packaging industry. This article will deeply analyze the reasons behind this phenomenon and explore feasible ways to resolve color deviation and other related pain points in the packaging industry.

1. Panoramic Overview of Pain Points in the Packaging Industry

Beyond the issue of color deviation, the packaging industry faces numerous other pain points that intertwine and restrict its development.

Environmental Pressure and Challenges in Sustainable Development

With the growing global awareness of environmental protection, consumers and regulatory authorities have increasingly strict requirements for the environmental performance of packaging materials. Traditional packaging materials such as plastics, which are difficult to degrade and cause severe environmental pollution, are gradually being restricted and phased out. However, the R&D and application of eco-friendly packaging materials like degradable materials and recycled materials still face challenges such as high costs and unstable performance. For instance, although biodegradable plastics have excellent degradation performance, their current production costs are generally 20% to 50% higher than those of traditional plastics, making many enterprises hesitant to adopt them. Additionally, the performance of eco-friendly packaging materials—such as strength and barrier properties—cannot fully meet the requirements of product packaging in some aspects, limiting their large-scale application. For packaging enterprises, balancing the need to meet environmental standards, control costs, and ensure product quality poses a significant challenge.

Resource Waste and Difficulties in Cost Control

Over-packaging is prevalent in the packaging industry, which not only wastes large amounts of materials and resources but also increases enterprises’ production costs. To pursue a luxurious visual effect, some high-end gift boxes adopt designs such as multi-layer packaging and excessive fillers, resulting in packaging material usage far exceeding actual needs. For example, certain high-end liquor gift boxes include not only outer cartons but also extensive fillers like foam plastic and silk satin inside. Most of these materials are discarded after the product is used, leading to enormous resource waste. Meanwhile, over-packaging also raises transportation costs, as the increased packaging volume occupies more transportation space. For enterprises, optimizing packaging design, reducing material waste, and lowering costs—while ensuring the packaging is aesthetically pleasing and protective—are urgent issues to address.

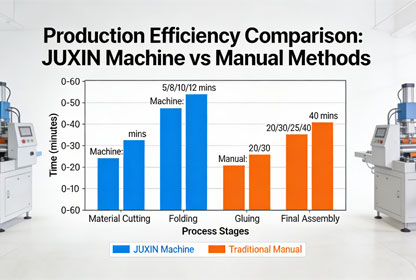

Insufficient Technological Innovation and Low Intelligence Level

The packaging industry as a whole suffers from insufficient technological innovation capabilities and low intelligence levels. In the production process, many enterprises still rely on traditional production techniques and equipment, resulting in low production efficiency and poor product quality stability. For example, some small-scale packaging enterprises use outdated printing equipment with low automation, requiring extensive manual operation. This not only increases labor intensity but also easily leads to human errors that affect product quality. In terms of packaging design, the application of innovative design concepts and technologies is relatively lagging, making it difficult to meet consumers’ increasingly diverse needs. At the same time, the packaging industry is still in its infancy in applying emerging technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI). The lack of intelligent packaging technology hinders efforts to optimize transportation methods, reduce costs, and improve product safety and traceability.

Fierce Market Competition and Diverse Customer Demands

The packaging industry faces fierce market competition, with a large number of enterprises and severe product homogeneity. Against this backdrop, customer demands for packaging products have become increasingly diverse—customers not only require packaging to have good protective functions and aesthetics but also expect it to feature personalized design, environmental performance, and intelligent interaction. For packaging enterprises, standing out in fierce market competition, meeting customers’ diverse needs, and enhancing customer satisfaction and loyalty are key to survival and development. However, due to insufficient innovation capabilities and poor insight into market demands, many enterprises struggle to respond quickly to customer needs, leading to a gradual erosion of their market share by competitors.

2. Solutions for Breaking the Deadlock: Comprehensive Approaches

Optimize Raw Material Procurement and Management

•Establish a strict supplier evaluation system: Packaging enterprises should develop a rigorous supplier evaluation system to comprehensively assess suppliers’ qualifications, production capacity, product quality, and environmental standards. They should cooperate with suppliers with a good reputation and stable product quality to ensure the reliability of raw materials. When signing procurement contracts with suppliers, enterprises should clearly define the quality standards and inspection methods for raw materials—such as indicators for paper whiteness, absorbency, and gloss, as well as ink hue, saturation, and lightfastness—and require suppliers to provide product quality test reports. Regular follow-ups and audits of suppliers should be conducted to supervise their production processes and quality control, ensuring the stability of raw material quality.

•Strengthen incoming inspection and storage management of raw materials: Before raw materials are stored in the warehouse, enterprises must conduct strict inspections, using professional testing equipment to verify various performance indicators of raw materials such as paper and ink, ensuring compliance with quality standards. Raw materials that fail to meet requirements should be resolutely returned. Meanwhile, enterprises should enhance the storage management of raw materials by setting appropriate storage conditions (e.g., controlling temperature, humidity, and light in the warehouse) based on the characteristics of the raw materials. For paper, direct sunlight should be avoided to prevent yellowing and brittleness; for ink, storage should comply with specified temperature requirements and shelf life to prevent deterioration. An inventory management system for raw materials should be established to monitor the quantity and quality of raw materials in real time, avoiding quality degradation caused by inventory backlogs or expiration.

Upgrade Printing Processes and Equipment

•Select printing methods rationally: Printing methods should be chosen based on the design requirements and product characteristics of high-end gift boxes. For gift boxes that require fine pattern printing, continuous-tone image printing, and high demands for color saturation and vibrancy, offset printing or gravure printing is preferred. For gift boxes needing large-area solid color printing or special effects, flexographic printing or screen printing can be considered. When selecting a printing method, enterprises should fully understand the advantages and disadvantages of each method and make a comprehensive judgment based on their own equipment conditions and technical capabilities. Additionally, enterprises can explore the combined application of different printing methods through technological R&D and innovation to achieve better printing results and color reproduction.

•Regularly maintain and update printing equipment: The maintenance and update of printing equipment are crucial for ensuring product quality. Enterprises should formulate a comprehensive equipment maintenance plan, conducting regular maintenance, cleaning, calibration, and repairs of printing equipment, and replacing worn parts in a timely manner to ensure the normal operation and precision of the equipment. For example, printing cylinders should be regularly ground to maintain surface flatness; rubber blankets should be inspected and replaced to prevent poor ink transfer caused by aging. Meanwhile, with the continuous advancement of technology, enterprises should update printing equipment in a timely manner, introducing advanced digital printing equipment, high-precision color management systems, and automated production equipment to improve production efficiency and product quality. For instance, some new digital printing equipment can realize on-demand printing, reducing printing setup time and material waste while enabling more precise color control and better color reproduction.

•Introduce color management software and equipment: To improve the accuracy and efficiency of color management, enterprises should introduce professional color management software and equipment. Color management software can uniformly manage and analyze the colors of design drafts, proofing samples, and printed products, and achieve color consistency across different devices by establishing color matching models. For example, X-Rite's Color iQC color management software can real-time monitor color changes during the printing process and automatically adjust printing parameters to ensure that the color of printed products matches the standard color sample. At the same time, enterprises should be equipped with high-precision color testing equipment such as spectrophotometers and densitometers to accurately measure and analyze the colors of inks, paper, and printed products during production, and promptly identify and correct color deviation issues.

Improve the Color Management Process

•Standardize the color mixing process and train personnel: A standardized color mixing process should be developed, requiring color mixers to operate strictly in accordance with the process. Before color mixing, a thorough understanding of ink batches and paper characteristics is necessary, and professional color mixing instruments should be used for precise measurement and analysis. For example, when preparing spot inks, the color data of the standard color sample should first be measured using a spectrophotometer based on the color requirements of the design draft. Then, the proportion of each ink should be calculated according to the ink matching guidelines provided by the ink supplier. During the mixing process, a high-precision electronic scale should be used to accurately weigh the ink, with detailed records kept. After mixing, a wire bar should be used to make a color sample, which is then compared with the standard color sample. The ink proportion is adjusted until the color similarity between the sample and the standard reaches over 95%. Additionally, enterprises should strengthen training for color mixers to improve their professional skills and color sensitivity. Regular industry training and technical exchange activities should be organized for color mixers to learn the latest color mixing technologies and methods, continuously enhancing their color mixing capabilities.

•Establish a full-process color management system: Color management should be integrated starting from the creation of design drafts. Designers should use a unified color mode (e.g., CMYK) and ensure that the color settings of the design software match the color space of the printing equipment. In the proofing stage, the same inks and paper as those used in the printing equipment should be adopted. Color management software is used to calibrate and match the proofing equipment and printing equipment, enabling the proofing sample to accurately simulate the color effect of the printed product. During the printing process, real-time monitoring of parameters such as ink color, ink layer thickness, and printing pressure is required. The color management system automatically adjusts printing parameters to ensure the stability of printing colors. In the finished product inspection stage, professional color testing equipment should be used to inspect products in accordance with unified color deviation standards (e.g., ISO 12647-2 standard). Only products with color deviation within the allowable range can be put on the market for sale. Meanwhile, enterprises should establish a product color file, recording the color data of the design draft for each order, the color parameters during the printing process, and the color inspection data of the finished product for future reference and traceability.

Address Environmental and Sustainable Development Challenges

•Increase investment in R&D of eco-friendly packaging materials: Packaging enterprises should actively respond to environmental calls and increase investment in the R&D of eco-friendly packaging materials. They should collaborate with research institutions and universities to carry out industry-academia-research joint research, develop new eco-friendly packaging materials, and improve the performance of eco-friendly materials while reducing costs. For example, R&D can be conducted on degradable paper made from plant fibers—with strength and printability comparable to traditional paper but capable of rapid degradation in the natural environment. Exploration can also be done on new synthesis methods for biodegradable plastics to improve their degradation rate and stability while lowering production costs. Enterprises can also modify and optimize existing eco-friendly materials through technological innovation—such as surface treatment of recycled paper to enhance its water and moisture resistance, expanding its application scope.

•Optimize packaging design to reduce material usage: In the packaging design stage, full consideration should be given to environmental protection and resource conservation, adhering to the principles of reduction, reuse, and recycling. The amount of packaging materials used should be reduced by optimizing packaging structure and dimensions. For example, a simple packaging design style should be adopted to avoid over-packaging; foldable and reusable packaging structures should be used to improve packaging utilization. Meanwhile, attention should be paid to the selection of packaging materials, giving priority to eco-friendly, degradable, and recyclable materials. Under the premise of ensuring the product’s protective function, thin materials should be used as much as possible to reduce material consumption. Furthermore, enterprises can enhance the added value of packaging through innovative design—for example, designing gift boxes to double as decorations or storage boxes—thereby reducing the generation of packaging waste.

•Establish a packaging recycling and reuse system: To achieve the sustainable development of packaging, enterprises should establish a packaging recycling and reuse system. Cooperation with downstream customers and recycling enterprises should be carried out to build packaging recycling channels, encouraging consumers to return used packaging to the enterprise or designated recycling points. Enterprises should sort, clean, and repair the recycled packaging, then reintroduce reusable materials into production. For example, recycled paper can be processed through deinking and pulping to produce recycled paper for packaging; recycled plastic packaging can be crushed and granulated to make plastic products or plastic pellets for sale. By establishing a packaging recycling and reuse system, enterprises can not only reduce consumption of natural resources and lower production costs but also reduce environmental pollution caused by packaging waste, achieving a win-win situation for both economic and environmental benefits.

Looking for a reliable packaging box manufacturer? Contact Juxin now!