How This Small Factory Doubled Output with One Smart rigid box making machine Upgrade?

Sep 24,2025

Sep 24,2025Introduction: The Turning Point for a Struggling Manufacturer

Imagine a bustling but overwhelmed small factory floor. Cartons of half-finished rigid boxes pile up near manual folding stations. Skilled workers, though diligent, are bottlenecked by repetitive, time-consuming tasks. The air is thick with the frustration of missed deadlines and the constant pressure to increase output without inflating costs. This was the daily reality for "Precision Packaging Ltd.," a family-owned business specializing in high-quality rigid box making machine operations for boutique clients. Their story is not unique. For countless small to medium-sized enterprises (SMEs), the leap from manual or semi-automated production to full, smart automation seems fraught with financial risk and operational disruption. However, for Precision Packaging, that leap became their defining moment of transformation. This article delves into how one strategic investment—a smart upgrade from JUXIN—didn't just incrementally improve their process; it fundamentally revolutionized their production capacity, doubling their output and securing their competitive edge. We will explore the tangible challenges, the detailed implementation process, and the remarkable results that any buyer in the packaging industry can learn from.

The Bottleneck Breakdown: Identifying the Limits of Traditional Rigid Box Production

Before the upgrade, Precision Packaging's operation was a classic example of traditional craftsmanship bumping against modern market demands. Their primary method relied on a decade-old, semi-automated rigid box making machine that required constant manual intervention. The process was riddled with inefficiencies:

-

Labor-Intensive Processes: Each box required manual feeding, alignment, and finishing. This not only slowed down the line but also led to inconsistencies in quality. A single skilled operator could only manage a limited number of boxes per hour.

-

High Rejection Rates: Minor errors in glue application or corner folding, often due to human fatigue, resulted in a significant percentage of boxes being rejected. This waste directly impacted their bottom line.

-

Inflexibility for Short Runs: The market increasingly demands small, customized batches. Their old machine required lengthy setup changes, making short-run productions economically unviable and causing them to turn away potential clients.

-

Skyrocketing Labor Costs: Dependence on manual labor meant their biggest cost was also their most variable and hardest to control. Finding and retaining skilled workers was an ongoing challenge.

The owner, Mr. Evans, knew something had to change. The goal wasn't just to buy a new machine; it was to find a smart rigid box making machine solution that could act as a force multiplier for his team. He needed a system that offered precision, speed, and, most importantly, adaptability.

The Solution Hunt: Why JUXIN's Smart Rigid Box Machine Stood Out

The search for a solution led Mr. Evans to evaluate several brands. The decision-making process was meticulous, focusing on total cost of ownership, technological sophistication, and post-sales support. The JUXIN rigid box maker consistently emerged as the frontrunner for several key reasons that directly addressed their pain points:

-

Integrated Automation: The JUXIN machine featured an end-to-end automated workflow. From automatic paper feeding and precise gluing to flawless folding and pressing, the machine minimized human touchpoints. This directly tackled the issues of labor dependency and consistency.

-

Intelligent Control System: Equipped with a user-friendly PLC (Programmable Logic Controller) and touchscreen interface, the machine allowed operators to store and recall settings for different box specifications instantly. This was the answer to their need for quick changeovers and handling custom rigid box orders.

-

Robust Construction and Precision Engineering: Unlike cheaper alternatives, the JUXIN automatic rigid box making machine was built with durability in mind. High-quality components ensured minimal downtime and long-term reliability, a critical factor for a production environment.

-

Data Reporting Capabilities: A standout feature was the machine's ability to generate simple production reports—tracking output numbers, run times, and identifying occasional stoppages. This data-driven approach empowered Mr. Evans to make informed decisions about efficiency.

The clincher, however, was JUXIN's commitment to customized rigid box making solutions. Their engineers didn't just sell a machine; they conducted a virtual analysis of Precision Packaging's specific box designs and production goals, confidently asserting that their equipment could handle the unique requirements.

The Upgrade Journey: Seamless Integration with JUXIN's Expert Support

A common fear when implementing new technology is the disruption it causes. Mr. Evans was pleasantly surprised by the smoothness of the transition, orchestrated by JUXIN's comprehensive service package.

-

Pre-Installation Consultation: JUXIN experts worked remotely with the Precision Packaging team to prepare the factory floor, ensuring the foundation and utilities were ready for the new rigid box making machine.

-

On-Site Installation and Training: A JUXIN technician arrived for the installation. The process was completed within two days. More importantly, the next three days were dedicated to hands-on training for the operators. This wasn't a generic tutorial; it was tailored to the specific types of boxes Precision Packaging produced.

-

Phased Implementation: Instead of a complete overnight switch, they ran the old and new machines in parallel for a week. This allowed the team to build confidence with the new JUXIN system without halting all production, mitigating risk effectively.

-

Ongoing Remote Support: The relationship didn't end after installation. JUXIN's support team remained accessible for remote diagnostics and troubleshooting, ensuring any teething issues were resolved swiftly.

This end-to-end support system transformed a potentially stressful capital investment into a collaborative partnership, highlighting the immense value of choosing a vendor that offers more than just hardware.

Measurable Results: Quantifying the Doubled Output and Beyond

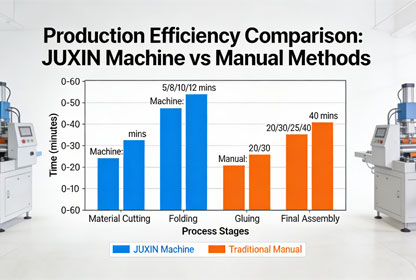

Within the first month of full operation, the impact of the JUXIN smart rigid box making machine was undeniable. The data spoke for itself:

-

Output Doubled: The production line's output increased from an average of 800 boxes per 8-hour shift to over 1,600 boxes. This 100% increase was achieved with the same number of operators, who were now upskilled to oversee the machine rather than perform manual labor.

-

Rejection Rates Plummeted: The precision of the automated gluing and folding systems reduced the defect rate from nearly 5% to under 0.5%. This dramatic drop in waste represented substantial savings on materials.

-

Enhanced Flexibility: Changeover times for new box designs were slashed from 45 minutes to under 5 minutes. This newfound agility allowed Precision Packaging to profitably accept smaller, high-margin custom orders they previously had to decline.

-

Improved Employee Morale: The workers were relieved from monotonous, strenuous tasks. They transitioned into roles requiring problem-solving and quality control, leading to higher job satisfaction and lower turnover.

The upgrade paid for itself much faster than anticipated, not just through increased revenue but also through significant cost savings on labor and materials.

Beyond the Hardware: The Lasting Advantage of JUXIN's Partnership

The success story of Precision Packaging underscores a critical lesson for buyers: the best rigid box making machine is part of a larger ecosystem. JUXIN excelled by providing a holistic solution. Their customized service for rigid box manufacturers meant they were invested in their client's success. Whether it was providing advice on material selection for a new client project or offering software updates to enhance machine functionality, JUXIN acted as a strategic partner.

For any business owner evaluating a rigid box making machine price, it's vital to look beyond the initial sticker price. Consider the value of reduced downtime, lower operating costs, increased flexibility, and the vendor's expertise. This total value proposition is where JUXIN truly differentiates itself in the market for industrial rigid box equipment.

Your Path to Transformation Starts Here

The journey of Precision Packaging from a constrained operation to a dynamic, high-output manufacturer is a blueprint for success. It demonstrates that with the right technology and the right partner, doubling your output is an achievable goal. The strategic upgrade to a JUXIN rigid box making machine was the catalyst for this remarkable turnaround.

Are you ready to unlock similar growth for your business? The first step is to have a conversation with experts who understand your unique challenges.

This article was created with the assistance of artificial intelligence to ensure data comprehensiveness and structural clarity, and has been meticulously reviewed and refined by our human experts to provide authentic, actionable insights for our readers. After all, the future of manufacturing lies in the synergy between human expertise and smart technology.