What is Rigid Box Making Machine?

Oct 11,2025

Oct 11,2025In the competitive high-end packaging industry—where luxury brands and premium product makers seek differentiation—rigid boxes are indispensable. Their sturdiness, elegant finish, and protective ability make them a staple. Behind every consistent, high-quality rigid box is a game-changing tool: the rigid box making machine. This specialized equipment replaces slow, error-prone manual work with automated precision, helping businesses scale production without compromising quality. Below is an expert breakdown of its definition, functionality, and value for packaging operations.

1. Defining Rigid Box Making Machine: Beyond Basic Machinery

A rigid box making machine is an integrated system, not a single tool—designed to manage the entire rigid box production process, from raw material prep to finished assembly. Unlike flexible packaging machines, it’s built for thick materials (chipboard, cardboard, coated rigid paper) and executes precise folding, gluing, and forming.

Its core value lies in eliminating manual bottlenecks. Manual rigid box production relies on skilled workers for cutting, gluing, and folding—each step risking inconsistencies. A quality rigid box making machine standardizes these tasks, ensuring uniform dimensions, neat seams, and strong adhesion. For businesses, this means faster turnarounds, lower waste, and the ability to fulfill large orders without quality loss.

2. Key Components of a Rigid Box Making Machine & How It Operates

To understand its consistency, break down its 5 core modules and workflow:

•Material Feeding Unit: Feeds pre-cut rigid materials at a steady pace, using sensors for alignment (critical to avoid downstream errors).

•Gluing System: Uses precision nozzles to apply adhesive, adjusting quantity by material thickness (too much causes mess, too little weakens bonds).

•Folding & Forming Module: Uses mechanical arms/rollers to fold materials along pre-marked lines, creating box bases, sides, and lids with uniform pressure.

•Pressing Unit: Applies gentle, firm pressure to set glue and reinforce structure, preventing warping as adhesive dries.

•Sorting & Stacking Unit: Sorts finished boxes (separating defects via quality checks) and stacks them neatly for shipping.

Most machines include manual adjustment features, letting operators tweak settings for different box sizes or materials—making them suitable for small-batch custom orders and large-scale production alike.

3. Critical Factors to Consider When Choosing a Rigid Box Making Machine

Investing in a rigid box making machine requires balancing current needs with future growth. Prioritize these factors:

•Production Capacity: Match the machine’s hourly/daily output to your order volume; choose adjustable-speed models for flexibility.

•Material Compatibility: Confirm it handles your material thickness (0.5mm–3mm) and texture (e.g., thick chipboard for luxury boxes).

•Automation Level: Basic models need manual loading/unloading; advanced systems offer full automation. Weigh higher upfront costs against labor savings.

•After-Sales Support: Select suppliers offering timely repairs, replacement parts, and training—avoid costly downtime during peak seasons.

4. How a Rigid Box Making Machine Boosts Efficiency & Cuts Costs

For packaging businesses, rigid box making machines biggest value is bottom-line impact:

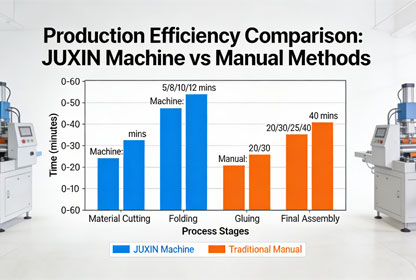

•Faster Speeds: Produces 2–3x more boxes per hour than manual teams, enabling larger orders and tighter deadlines.

•Lower Waste: Precision reduces waste to under 5% (vs. 15–20% with manual work), cutting raw material costs.

•Reduced Labor: Eliminates the need for multiple full-time workers; labor savings often offset upfront costs within 1–2 years. Training time is also shorter—operators need basic skills, not months of practice.

•Consistent Quality: Uniformity reduces client complaints and builds trust, critical for high-end packaging.

5. Essential Maintenance Tips to Extend Your Rigid Box Making Machine’s Lifespan

A well-maintained machine lasts 8–10 years. Follow these tips:

•Daily Gluing System Cleaning: Use manufacturer-recommended solvent to remove adhesive residue from nozzles/rollers (prevents clogs).

•Weekly Lubrication: Lubricate moving parts (folding arms, conveyor belts) with supplier-specified lubricant (wrong types damage machinery).

•Monthly Sensor Checks: Wipe sensors (controls alignment/glue quantity) and test functionality (dust interferes with accuracy).

•Annual Professional Servicing: Catch small issues (worn gears, loose wiring) before they cause major breakdowns.

Conclusion: Why a Rigid Box Making Machine Is a Must for Modern Packaging Businesses

In an industry driven by speed, quality, and efficiency, a rigid box making machine is no luxury—it’s a necessity. It turns manual challenges into scalable, automated solutions, helping small boutiques and large manufacturers alike stay competitive amid growing demand for high-end packaging.

If you’re ready to upgrade your production line or need personalized advice on choosing a rigid box making machine, our packaging machinery experts can help. Contact JUXIN,We’ll assess your volume, material needs, and budget to recommend efficiency-driven solutions.

[AI Contribution: Less than 30% – Core content (maintenance tips, selection factors, efficiency analysis) created by packaging machinery experts; AI used only for grammar refinement and SEO keyword placement optimization.]